Product Description

We offer a series of Load Tap Changer (LTC) maintenance courses to teach the unwritten knowledge and skills that can

only be obtained through years of hands-on experience. Our comprehensive training programs run full circle—from operational concepts and recommended maintenance practices to modelspecific assembly techniques and OEM design changes.

To be sure participants maximize their experience and hands-on learning, we limit class sizes to around 15 students.

Course offerings target critical skill sets needed for substation engineers, field crews and apprentices to be effective:

• Theory of LTC Operation and LTC Designs

• Common Failure Modes

• LTC Inspection Preparations

• Parts Identification

• Internal Parts Inspection, Removal and Installation

• Contact Wear Patterns

• Identification of Improper Operation

• Unit Timing and Calibration

• OEM Design Changes

• Vacuum Bottle Monitoring Circuits

LTC Courses Offered:

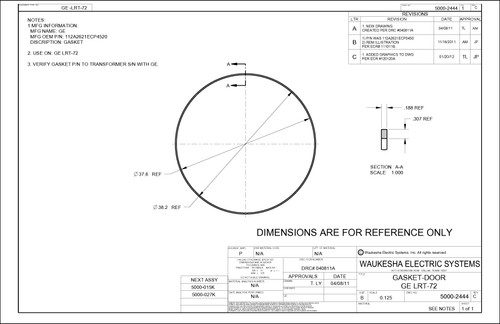

| • GE LRT-200 Series | • GE LRT-65/83 |

| • FPE TC-525, TC-546 | • Siemens-Allis TLH-20/21 |

| • Reinhausen Type RMV-II | • Westinghouse UTT, UTT-A, UTT-B |

| • Waukesha® UZD® | • McGraw 550 Series |

| • GE LRT-68/72 | • GE LRT-38/48 |

| • Siemens-Allis TLS/TLF | • ABB UZ-Type |

Click here for more information on what each class covers

Each attendee receives a course manual with easy-to-use field reference guides along with many pages of technical resources. Contact us for customized class sizes and/or specialized training.

Monday is typically a travel/set up day, and class begins Tuesday at 8am Central time.